The best Side of DTF Transfers

The best Side of DTF Transfers

Blog Article

How long do DTF transfers very last when they are pressed? Do they crack over time? In the event your garment is retained in fantastic situation (averting harsh climate and Bodily activity), a normal DTF transfer can final for 50+ wash cycles.

push: The well prepared movie is put on to The material Together with the printed side down. employing a warmth press, the movie is pressed on to the substrate of option for the proposed software configurations.

Why is my DTF transfer not sticking/adhering? you should definitely are urgent at the right temperature with satisfactory and constant stress.

ahead of we delve into the sensible components of DTF transfer placement, let’s unravel some of the necessary principles:

Professional tip: In the event your text is at the most width and will not appear large enough, think about using a taller font as an alternative to stretching the font to generally be taller (which distorts it and makes it considerably less legible).

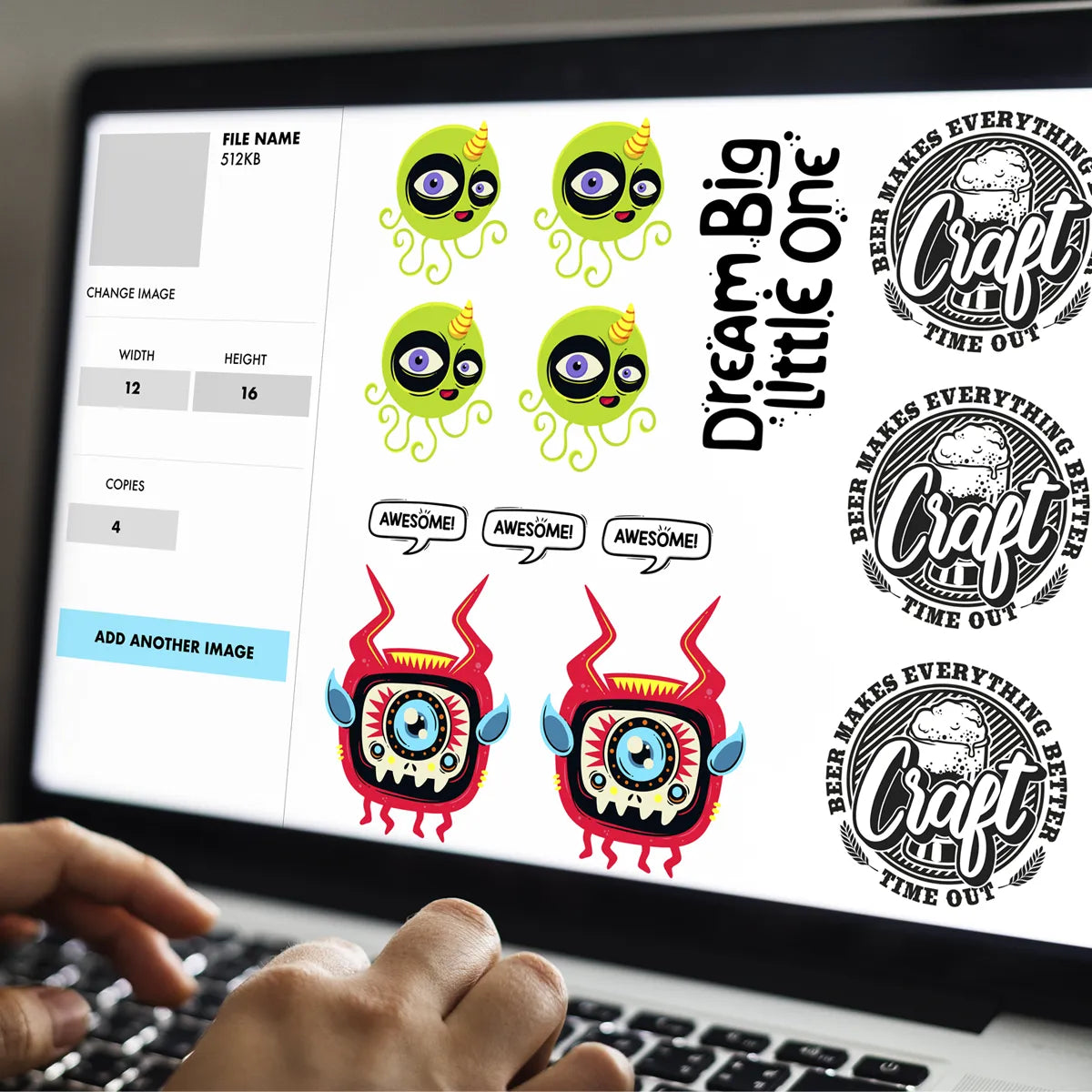

Professional tip: Print out your design and style at full preferred measurement using your residence or Place of work printer. you may "tile" the look (on the list of print options), then tape the internet pages alongside one another, Reduce off the perimeters, and place on the garment to be printed to check out if it suits in true existence.

the procedure begins with creating a electronic design and style that is certainly printed onto the film applying DTF supplies. superior-quality inks make sure vivid hues and intricate details are captured to the movie.

4. Curing: The movie is then cured utilizing a heat push or oven. This move is important because it makes certain that the adhesive solidifies and the look is able to be transferred.

altering your structure by thickening up these details or adding an define may also help mitigate this challenge, in addition to adhering to suitable software and urgent Recommendations.

This is usually exactly where you will see the bold terms "SECURITY," "function team," or even the hashtag of the moment. Larger logos also get the job done very well.

rework your textile printing abilities these days with our unmatched DTF printing machine assortment and witness the amazing affect of point out-of-the-artwork direct to film printer technologies on your organization.

three. Applying the Adhesive: A powder adhesive is placed on the soaked ink just after printing. This adhesive enables the design to bond with The website material when heat pressed.

This printer makes use of water-dependent CMYK and white pigment inks to print the look in reverse. The white layer is printed past as a backing layer. This tends to make the colors to the substrate surface additional lively.

Whether you are new on the STAR plan or contemplating a switch to your STAR credit rating, assessment our sources for an entire overview.

Report this page